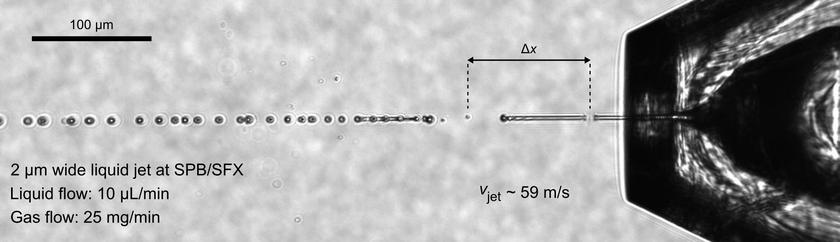

Image of a 2 µm liquid jet produced by a GDVN. The X-ray pulses arrive at a repetition rate of 0.56 MHz and create gaps in the liquid column.

Liquid Sample Delivery

The Sample Environment and Characterization group at the European XFEL provides users with different options to bring their liquid samples into the beam. Depending on the user's requirements and sample demands, we provide standard injection devices or collaborate with users on optimized solutions.

As shown in the expandible list below, SEC is able to offer different types of devices, whose fabrication in based on the two-photon polymerization (2PP) 3D printing technique. The devices are tailored to serve the users purposes and the different characteristics of the sample to be measured. A detailed description of the different devices and sample delivery strategies offered by SEC is given by M. Vakili et al. The SEC liquid jet team contantly develops and further improves these and other liquid sample delivery methods.

A repository of 3D designs for liquid sample delivery at the European XFEL can be found here:

https://github.com/flmiot/EuXFEL-designs

SEC also assist users bringing their own injection systems to European XFEL instruments. There is always a sample injection person responsible for each beamtime. We are happy to discuss and support your projects, please contact us by sec@xfel.eu.

Liquid Sample Delivery Devices

Gas Dynamic Virtual Nozzles, GDVN

GDVN has been used with a variety of crystals sizes and buffer solutions, see the jet stability in the picture above. SEC offers these devices with different inner channels orifices (30-100 µm diameter) for both, gas and liquid channels, and different distances between the orifices, depending on the sample parameters and jet velocities required.

Rayleigh Jet Nozzles

We developed a 3D printed cone with 5.35 mm length connected to a stainless steel tubing as a nozzle to generate Rayleigh Jets. The nozzle is connected with a PEEK tubing and fitting to a HPLC pump and is used for high flow rates (1-30 mL/min). The jet and the droplets size are determined by the size of the inner diameter of the nozzle orifice (25-200 µm).

High Viscosity Extrusion Injectors, HVE

This injector system is composed of a hydraulic cylinder, which is driven by a high-performance liquid chromatography (HPLC) pump, a sample reservoir and a nozzle tip. Here, a low-pressured coaxial helium flow along the inner capillary in the tip stabilizes the highly viscous samples (gel-like nature) stream.

A mixing HVE device in under development.

Double Flow Focusing Nozzles, DFFN

DFFN utilizes an inner (sample) stream which is focused by a coaxial, faster-flowing outer liquid (usually ethanol). The sample stream propagates as a thin and very stable jet within the ethanol jet. The ethanol jet itself is then focused by coaxial gas flow (as in the traditional GDVN). As the jet is primarily formed by the sheath liquid, the sample consumption can be reduced compared to a regular GDVN.

Mixing Injectors

These microfluidic devices allow a precise control over fluids due to the inherent laminar flow. The short pathways in microchannels (75-250 µm) promote fast and controlled diffusive-based mixing which is essential when it comes to a systematic analysis of mixing-induced reaction kinetics and structural transitions of (bio)macromolecules.

Electrospray Ionization

Electrospray ionization uses a strong electric field to produce aerosols from small particles in liquid suspension. The aersols can then be delievered to the interaction regions of the scientific instruments using an aerodynamic lens.