XFEL: European XFEL installs its most advanced “eye” yet

European XFEL installs its most advanced “eye” yet

The European XFEL, the world’s largest X-ray laser, has completed the development and successful installation of its first advanced detector. The Large Pixel Detector (LPD) is a cutting-edge X-ray “camera” developed by European XFEL and the Science and Technology Facilities Council (STFC), based at Rutherford Appleton Laboratory near Oxford in the UK. It is the first fully functional X-ray light detector to record at a rate of 4.5 MHz—4.5 million pictures per second, fast enough to keep up with the European XFEL’s high repetition rate of 27 000 pulses per second, which are arranged into shorter-timescale bursts. The LPD will enable the Femtosecond X-Ray Experiments (FXE) instrument, which will be available for users in September 2017, to take clear snapshots of ultrafast processes such as chemical reactions.

European XFEL Detector Development group leader Markus Kuster said: “The years of intensive collaboration with the Rutherford Appleton Laboratory on the LPD have paid off, and resulted in a unique detector that can record data on the timescale of a billionth of a second.”

The Large Pixel Detector in its final location as part of the FXE instrument.

The LPD operates far beyond the scope of any commercial detector or camera. Its design enables the detector to record data every 222 nanoseconds (billionths of a second)—an unprecedented rate that allows it to capture individual ultrashort X-ray laser flashes from the European XFEL. Additionally, the detector has a very high so-called dynamic range: It can pick up signals as weak as a single particle of light, also known as a photon, and as strong as a flash of several tens of thousands of photons in two neighbouring pixels.

In a typical experiment at the European XFEL, users will place samples in the path of incoming X-ray laser pulses in order to study their structure at the atomic level. Detectors will acquire X-ray laser light scattering off the sample, which often consists of individual molecules. The LPD’s high dynamic range allows for very high resolutions showing the finest details from samples.

European XFEL leading scientist and FXE instrument leader Christian Bressler said: “We now have one of the ‘eyes’ for our instrument. We are proud to have received the fastest X-ray detector on this planet! The European XFEL Detector Development group and the colleagues from Rutherford Appleton Laboratory have worked hard and efficiently to get this detector up and running, alongside our software and IT groups.”

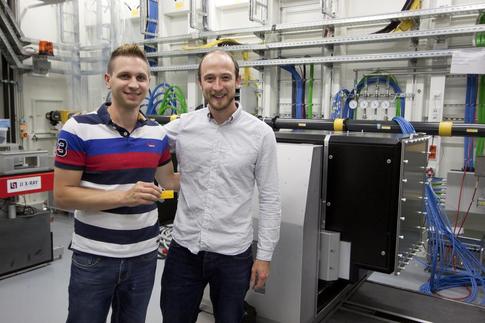

European XFEL LPD project lead Philipp-Michael Lang with STFC Application Engineer Matthew Hart Matt Hart at the handover of the LPD 'keys'.

Development of the LPD began in 2006. Several prototypes were developed that used smaller numbers of modules, allowing European XFEL scientists to become acquainted with and further develop the detector’s subsystems. In 2014, the Rutherford Appleton Laboratory began working on a large, 16-module device for the FXE instrument. Further detectors that can record at the needed 4.5 MHz are on the way for the other instruments at the facility: the Adaptive Gain Integrating Pixel Detector (AGIPD), developed by European XFEL’s close partner DESY, and the DEPFET Sensor with Signal Compression (DSSC), developed by a special consortium led by European XFEL. On 1 September, the facility will hold its official inauguration in Schenefeld.

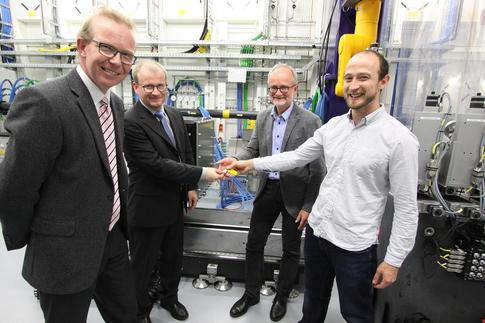

Official handover of the 'keys' to the LPD from the Rutherford Appleton Laboratory. From left: STFC Technology Department Division Head Marcus French, European XFEL Detector Develop Group Leader Dr Markus Kuster, European XFEL Managing Director Prof. Dr Robert Feidenhans'l and STFC Application Engineer Matthew Hart.