XFEL: Molecular motion in tire rubber

Molecular motion in tire rubber

Scientists have observed the molecular motion of rubber components typically used in automobile tires—polybutadiene and carbon black—with the world’s fastest time resolution. The study reveals a clear interaction between the two components on the atomic scale, paving the way towards improved diagnostics of tire rubber degradation and the development of materials with enhanced durability.

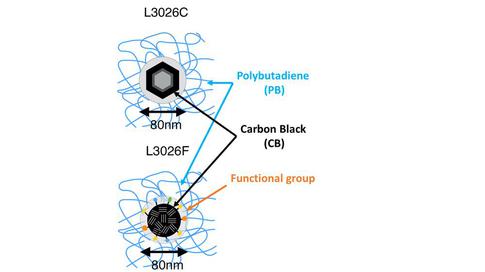

Structure of two different rubber samples. Top: Schematic illustration of sample L3026C of tire rubber containing graphitized carbon black (CB), with little interaction between CB and polybutadiene (PB). Bottom: Schematic illustration of sample L3026F of tire rubber containing non-graphitized CB. The CB surface and PB are strongly bonded and largely interact, resulting in better properties of the material for automobile tire performance.

Tire rubber is a composite material that typically includes synthetic rubber, such as polybutadiene, and added nanoparticles, such as carbon black, to improve its physical properties. During driving, strong forces act on the tire, causing its components to move against each another, which can lead to wear and degradation of the material. To evaluate tire performance, it is therefore important to understand not only the static structure of the complex particle network formed by the polymer and the nanoparticles, but also their interaction and respective movements, as these dynamics directly influence material properties such as wear resistance. Because some of these molecular movements happen extremely quickly, time-resolved measurements at atomic resolution on the fastest possible time scale are critical for developing and validating dynamic models of such materials.

Scientist Tokushi Sato at the SPB/SFX instrument. Copyright: European XFEL

An international research team led by scientists from the University of Tokyo, Ibaraki University, and European XFEL has now observed the molecular motion within samples of polybutadiene and carbon black, which occurs naturally as a result of the material structure, with a time resolution of 890 nanoseconds (billionths of a second)—the fastest resolution obtained in such studies so far—at the European XFEL’s SPB/SFX instrument.

“Using the recently developed method of diffracted X-ray blinking, we simultaneously detected fast changes in the polymer chains and in the additive nanoparticles on the atomic scale,” says Tokushi Sato from European XFEL, one of the corresponding authors of the publication. “We observed a clear interaction between polybutadiene and carbon black, indicating that the mobility of polybutadiene differed significantly depending on the type of carbon black added.” Each sample contained a different kind of carbon black. The experiment revealed that, in one sample, the polybutadiene moved much faster on the carbon black particle surface than in the other—resulting in poorer properties for automobile tire performance than the sample in which the two components were more strongly bound. The results may lead to improved methods to study tire rubber degradation in the laboratory during development and thus to devise materials with enhanced durability.

Alongside European XFEL, the study involved research institutions from Japan, Australia, and New Zealand as well as the Japanese company Sumitomo Rubber Industries.

Reference:

“Direct observation of 890 ns dynamics of carbon black and polybutadiene in rubber materials using diffracted X-ray blinking”, Masahiro Kuramochi et al., Appl. Phys. Lett. 123, 101601 (2023), DOI: 10.1063/5.0157359

Contact:

Dr Tokushi Sato

Tel: +49-40-8998-6864

E-mail: tokushi.sato@xfel.eu

Dr Richard Bean

Tel: +49-40-8998-6843

E-mail: richard.bean@xfel.eu

Dr Bernd Ebeling

Tel: +49-40-8998-6921

E-mail: bernd.ebeling@xfel.eu