XFEL: Ultrafast surface processes observed

Ultrafast surface processes observed

In a world first, an international team of scientists led by European XFEL and the University of Siegen has demonstrated that the intense pulses produced by an X-ray laser can be used to investigate ultrafast processes occurring on and just below material surfaces with unprecedented depth and time resolution. This allows researchers to capture processes that are more than a billion times faster than what could previously be observed. The results, which the team has just published in Physical Review Research, pave the way for versatile applications that rely on our understanding of ultrafast surface dynamics. Examples are the laser processing of material surfaces to create tailor-made nanoscale structures or the realization of compact laser-based particle or radiation sources.

Using intense laser pulses, nanoscale surface structures can be created with optimized optical, mechanical, and chemical properties. Such tailored structures play a decisive role in many fields with significant societal and economic impact. They can be used to fashion antimicrobial coatings, to improve the bonding of dental implant screws with bone, and to build advanced optical components with high damage thresholds. To be able to better create these structures and comprehend their effects, scientists first need to observe and understand the ultrafast processes that happen when the intense femtosecond laser pulses used in the surface processing hit the material and react with it.

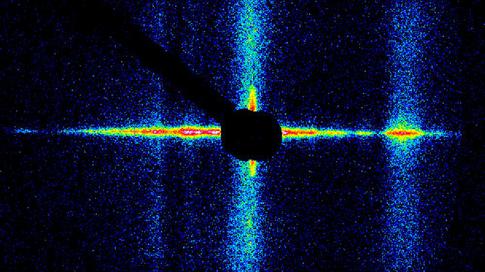

Grazing-incidence small-angle X-ray scattering image obtained from a multilayer sample, measured using single X-ray pulses of the SACLA X-ray laser in Japan. The central black circle is the beamstop used to block the main mirror-like reflection peak, which is much more intense than the scattering pattern. The pattern contains information on the depth-resolved density profile (horizontal axis) and the surface structure (vertical axis).

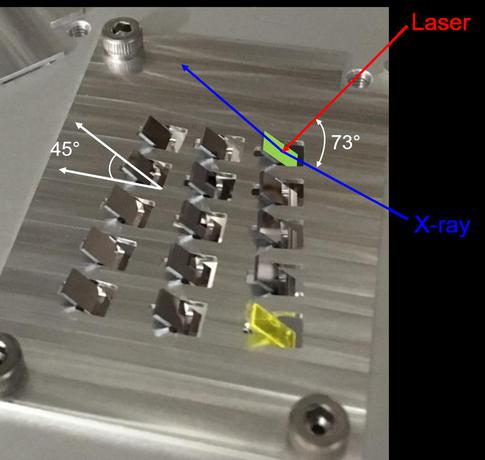

Multilayer samples used in the experiment. Each sample has a size of 4 x 7 mm. A new sample is used after each laser irradiation.

“However, many physical effects are still missing even in these particle-in-cell simulations,” says Motoaki Nakatsutsumi from European XFEL, who was the principal investigator of the experiment. “Our method will help to further improve the modelling of laser–solid interactions and to devise new applications for them.” In particular, the researchers expect the unprecedented possibilities enabled by their new technique to open up new perspectives for laser material processing and high energy density science.

Publication:

L. Randolph, M. Banjafar, T.R. Preston, T. Yabuuchi, M. Makita, N.P. Dover, C. Rödel, S. Göde, Y. Inubushi, G. Jakob, J. Kaa, A. Kon, J.K. Koga, D. Ksenzov, T. Matsuoka, M. Nishiuchi, M. Paulus, F. Schon, K. Sueda, Y. Sentoku, T. Togashi, M. Bussmann, T.E. Cowan, M. Kläui, C. Fortmann-Grote, L. Huang, A.P. Mancuso, T. Kluge, C. Gutt and M. Nakatsutsumi, “Nanoscale subsurface dynamics of solids upon high-intensity laser irradiation observed by femtosecond grazing-incidence x-ray scattering”, Phys. Rev. Res. 4, 033038 (2022)

Science contacts:

Dr. Motoaki Nakatsutsumi

Tel: +49 40 8998 6966

Email: motoaki.nakatsutsumi@xfel.eu

Dr. Lisa Randolph

Tel. +49 271 740 3761

Email: Lisa.Randolph@uni-siegen.de